Business transformations

| |

On this page:

| |

Patagonia | |

Image reproduced from Patagonia website. The following case study is paraphrased from Business & Society: Ethics, Sustainability, and Stakeholder Management. The ChallengeFounder and owner of outdoor lifestyle company Patagonia, Yvon Chouinard found that cotton was particularly damaging due to its dependencies on pesticides, insecticides, and defoliants. “To know this and not switch to organic cotton would be unconscionable,” said Chouinard. He gave his managers 18 months to make the switch. The SolutionThis was a difficult move in 1994, even for a founder who owned most of the company’s stock. Organic cotton was rare at the time, costing 50–100 percent more than traditional cotton. The risk was huge, because a fifth of Patagonia’s products were made from cotton. Suppliers balked and the rank and file grumbled, but Chouinard said that they had to do it or the company would not sell cotton again. The ResultsThe risk paid off. Patagonia’s cotton sales rose 25 percent, and the move set up an organic cotton industry that thrives today. Chouinard ran away with TriplePundit.com's 2010 Most Sustainable CEO award. External linksPatagonia website's Footprint Chronicles® | |

3M Company | |

Image reproduced from 3M website. The following case study is paraphrased from Business & Society: Ethics, Sustainability, and Stakeholder Management. The ChallengeCreating 3M’s Pollution Prevention Pays program as a multiproduct, multiprocess approach to manufacturing. The Solution“3M’s leadership has recognized that the company's long-term success springs from the principles of ... Stewardship to the environment, contributions to society, and the creation of economic value.” 3M adopted a long-term, comprehensive, beyond-compliance, environmental program. The company's 'Lifecycle Management' program is designed to minimize environmental impact from the product design right through to customer use and disposal. The Results

Further reading | |

Ricoh | |

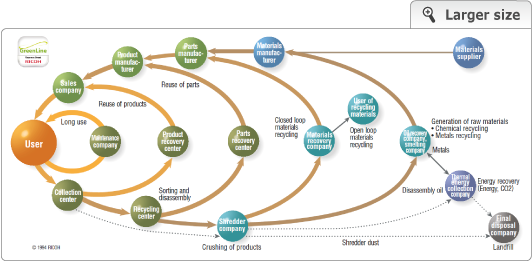

The ChallengeTo provide a product-portfolio planning tool that shows the various end of life options for products, components and materials. The SolutionThe Ricoh Comet Circle™, shows how products, components and materials might be repaired, recovered, refurbished and resold. In order to understand the diagram below, start from the top right hand corner and then work your way around the circles.

The circles show a progression from the most desirable - tightest loops, to the least desirable - landfill. The ResultsIntroduced in 1994, Ricoh management used the Comet Circle™ to plan their GreenLine products, which quickly become a success story and now match new equipment sales (source). Further readingSee the Ellen MacArthur Foundation's Ricoh case study | |

Feedback

We would welcome your feedback on this page: